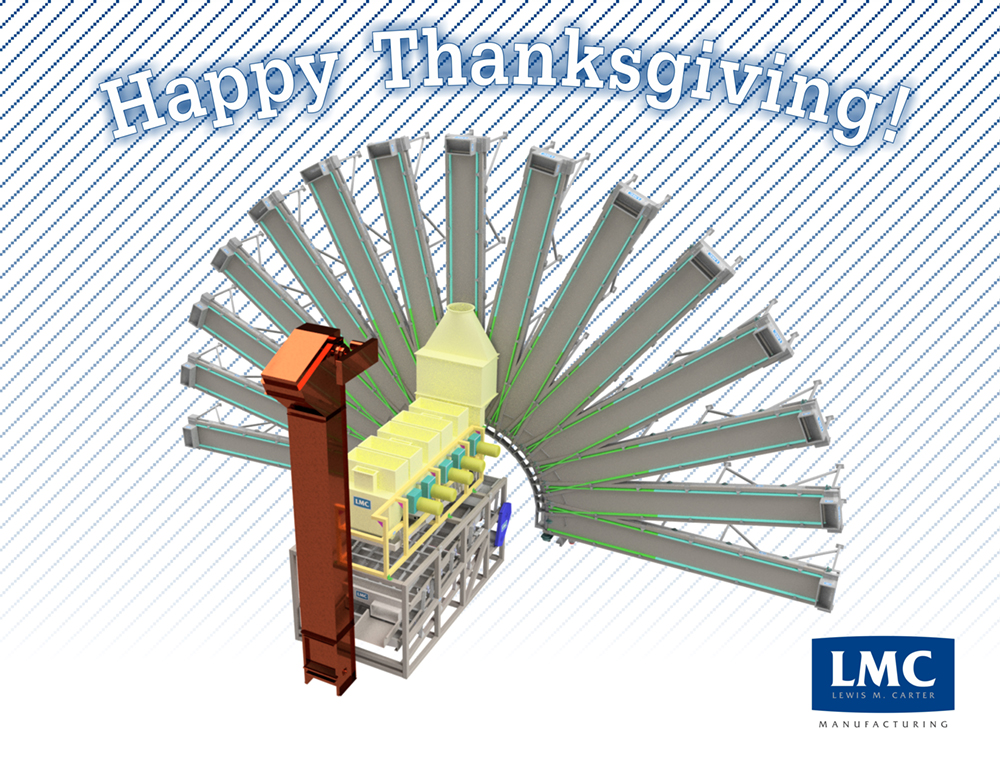

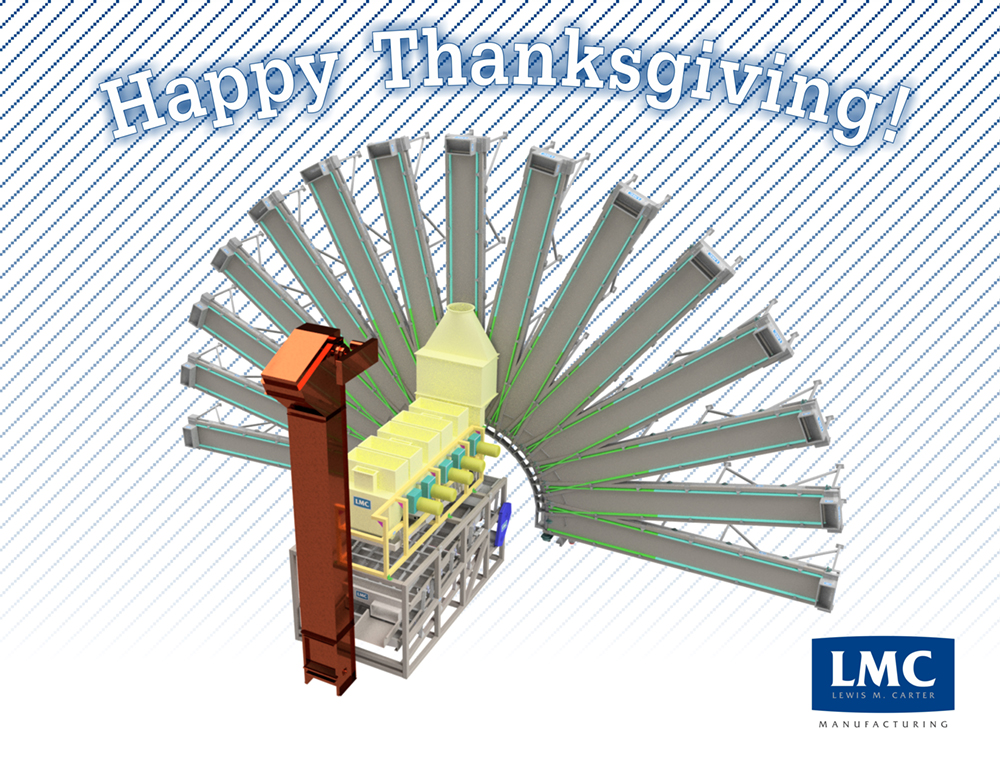

Happy Thanksgiving from LMC!

We would like to wish a Happy Thanksgiving to all of our friends and LMC family this year.

We are grateful and blessed for the time we get to share with each other.

Safe travels!

We would like to wish a Happy Thanksgiving to all of our friends and LMC family this year.

We are grateful and blessed for the time we get to share with each other.

Safe travels!

We would like to take a moment to honor all our friends and family who have made sacrifices for the greater whole of the country we live in.

Your efforts are appreciated and we thank you!

We have made some key structural changes to our Sales and Service departments which will maximize the strengths of our team players.

This is just a small part of the many opportunities we seek to better serve our customers.

Long time LMC customers and friends, AGD, based in General Deheza, Cordoba, Argentina, recently held the grand opening of their latest processing facility, a LMC designed almond hulling and shelling plant in Mendoza Province, Argentina.

While Mendoza is noted for its wine production and has had small almond facilities for years, this is the first commercial almond operation built to world processing standards.

Argentinian President, Sr. Mauricio Macri, was there to join in, to speak and to congratulate the AGD team and the Urquia family for their vision and action in developing a larger almond market for Argentine farmers.

Congratulations to the LMC design team, led by company president, Joey Trice, for a job well done. Joey was there for the commissioning of the plant and the initial training of the AGD personnel in using LMC almond equipment. Initial reports from the first year’s operation are that their customers are pleased and that the almonds are fantastic.

AGD is an integrated agricultural industrial complex whose main activity include production of corn, peanut, soy and sunflower oils, vegetable protein meals, shelled peanuts, as well as manufacturers of mayonnaise, ketchup and other sauces. AGD and LMC have been friends and for over 35 years.

Thank you and congratulations!

Alfons Visser and me inside Golden’s latest peanut shelling plant in Hartswater. I first met Alfons about 12 years ago and we began both our business and personal relationships. He has since partnered with Golden to expand their operations here in South Africa. Without any doubt, Dirk Lindsey, who worked here as Operations Director for 2 years, was a vital player in getting this project started. Dirk, a native of Stephenville, Texas, is so respected here, the made him an honorary Afrikaaner. Well done Dirk.! You’d be so proud of Dawie and Manie.

The first peanuts going into a LMC shelling cylinder in Golden Peanut and Tree Nut’s new peanut shelling plant in Hartswater, Northern Cape, Republic of South Africa. The LMC process design has been installed here using some new LMC equipment as well as used LMC from within Golden’s system in the U.S.

All involved, particularly Dawie Snyman, on the left and Manie van der Merwe, have devoted endless hours to take an idea and make it a reality. Jackie Williams and I were in constant contact advising, as well as reviewing the installation ‘s progress. These two built teams.as well a new shelling. So happy for them and those working with them.

While there has been a lot of LMC equipment in South Africa since 1976, This is the first complete LMC design in South Africa and from what we saw today, it will meet and exceed all expectations. Jackie Williams and I were elated to be here and help with an amazingly trouble free start up.

There were a lot of smiles in Hartswater today! Our thanks to all involved.

My and Rapie Visser’s best sides as we check out the installation of his latest LMC machines. As always, Rapie did a great job. This is an inshell pecan cleaning and grading facility at Besters in Hartswater, Northern Cape, South Africa. He is receiving, cleaning and grading around 8 tons per hour. Jackie Williams and I visited Bester and 3 more new LMC installations in Hartswater.

Working for Golden Peanut and Tree Nut around the world. This is a peanut receiving cleaner in Hoopstad, North West Province, South Africa. Whether the U.S., South Africa or Argentina, we certainly appreciate our business with Golden.

We received some great shots of a job we finished in India. LMC did the design work and the customer built and installed everything based off of our designs. However, it was really by the grace of God we were able to complete this project literally half a world away from Donalsonville. Here’s why; part way through this project a computer glitch deleted a large portion of what we had completed. We had some reference files which weren’t affected so, luckily, we didn’t have to start completely from scratch but most of our 3D files had to be completely redone so it might has well have been. We took a deep breath, redoubled our efforts, and forged ahead. These things happen but problems are really solutions in disguise. This data loss did give us the opportunity to see things with a fresh eye. As a result, there were some minor changes in the process that were made to our original designs versus what was actually built. These changes actually improved our original intent. In the end, this AgroCrops facility is now responsible for cleaning and sizing shelled peanuts at a rate of 25,000 pounds per hour!